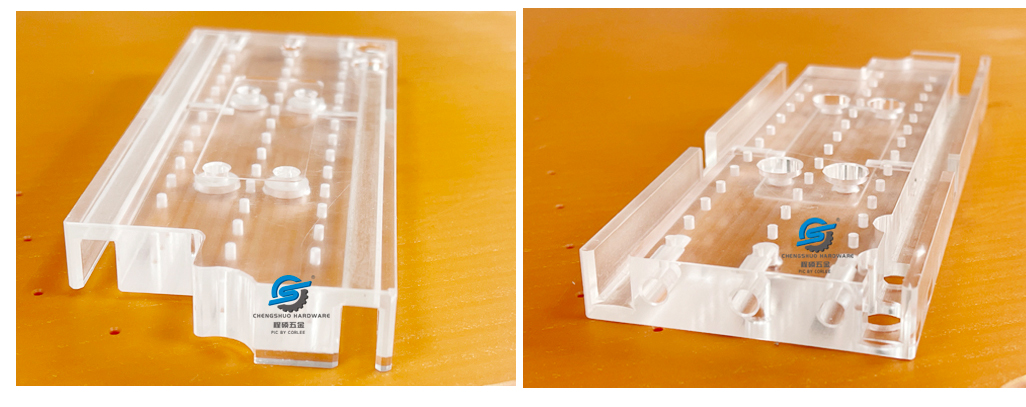

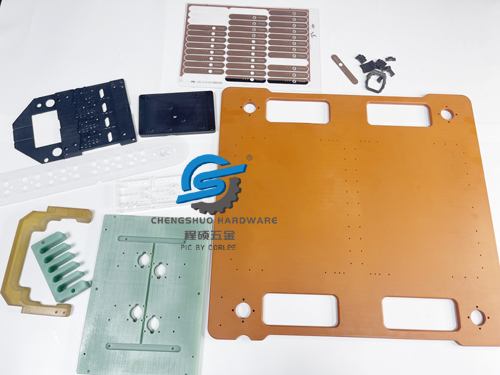

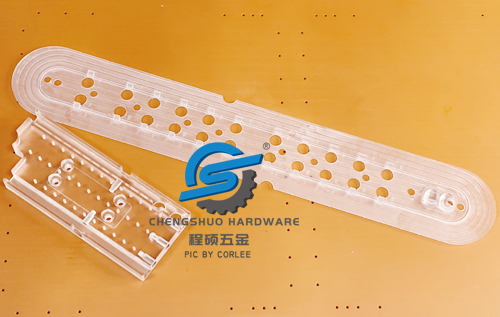

CNC machining na acrylic kayayyakin iya cimma mafi hadaddun Tsarin, rage fasa a cikin acrylic abu a lokacin.inji, da kuma cika madaidaicin buƙatun don samfuran.

Polymethyl methacrylate (CH3│-[- CH2—C——]- │ KASHI3) yana da kyawawan kaddarorin injiniyoyi masu kyau, matsayi a cikin mafi kyau tsakanin manyan robobi. Ƙarfin ƙarfinsa, lanƙwasa, da matsawa sun fi polyolefin girma, sannan kuma ya fi polystyrene, polyvinyl chloride, da dai sauransu, amma tasirinsa ba shi da kyau. Amma kuma yana da ɗan kyau fiye da polystyrene.physical Properties.

PMMA yana da ƙarfin injina mai girma: ƙwayar ƙwayoyin ƙwayoyin dangi na PMMA kusan miliyan biyu ne. Yana da dogon sarkar polymer, kuma sarƙoƙin da ke samar da kwayoyin suna da laushi sosai. Saboda haka, PMMA yana da ƙananan ƙarfin ƙarfi kuma yana da tsayayya ga shimfiɗawa da tasiri. 7 zuwa 18 sau fiye da gilashin na yau da kullum. Akwai nau'in gilashin kwayoyin halitta wanda aka yi zafi da kuma shimfiɗawa, wanda aka tsara sassan kwayoyin halitta a cikin tsari mai mahimmanci, wanda ya inganta mahimmancin kayan aiki.

Acrylic yawanci ana amfani dashi a cikin masana'antu don samarwa da kera bangarorin kayan aiki da murfi, Har ila yau, na daban-daban na tiyata da kayan aikin likita, kayan gida: kayan wanka, kayan aikin hannu, kayan kwalliya, brackets, aquariums, da dai sauransu.

Lokacin amfani da CNC don aiwatar da samfuran acrylic, kuna buƙatar kula da waɗannan abubuwan:

1. CNCTsara Shirye-shiryen Don AcrylicMachiningGudanarwa

Don acrylic (Polymethyl methacrylate, PMMA), cikakkun bayanai na shirye-shirye na samfurin ya kamata a tsara su bisa ga siffar samfurin, kamar saurin ciyar da kayan aiki da saurin juyawa a lokacin.injisarrafawa. Dangane da ainihin siffar samfurin, ya kamata a inganta tsarin shirye-shirye da kwarara don rage lalacewa yayin sarrafawa.

Lokacin amfani da CNCinjiacrylic, yana da matukar muhimmanci a saita daidaitaccen adadin abinci. Idan yawan ciyarwar ya yi sauri, PMMA na iya karya saboda matsananciyar yankewa. Matsakaicin ciyarwa mai sauri na iya haifar da sassa don fita daga wurin aiki ko barin rashin ƙarfi a ɓangaren; jinkirin farashin ciyarwa kuma na iya samar da sassan da ba daidai ba tare da m, saman da ba a gama ba.

2. The Selection Of Tools A Acrylic Processing Dole ne ya dace

Gudanar da zanen gadon acrylic yana buƙatar amfani da kayan aikin da suka dace. Dangane da nau'in kayan aiki, kayan aikin da aka saba amfani da su sun hada da masana'anta na ƙarshe, masu yanke hanci na ball, masu yankan lebur, da dai sauransu. don sarrafa gefuna na rubutu da zane-zane, kuma mai yankan hanci yana cikin siffar baka kuma ya dace da sarrafa madaidaicin tsari da lanƙwasa.

Kayan wuka kuma yana da mahimmanci. Alal misali, ƙarfe mai sauri yana yanke acrylic, amma baya samar da kyakkyawan ƙare. Kayan aikin lu'u-lu'u na iya haɓaka ƙarewar ƙasa amma suna da tsada sosai. Carbide sau da yawa kayan zaɓi ne don yankan acrylic CNC.

Don CNC machining acrylic, ana kuma ba da shawarar yin amfani da kusurwar rake mai yankan digiri na 5 da ƙarin kwana na digiri 2.

Bugu da ƙari, kayan aikin yankan, dole ne kuma kula da zurfin yankewa, saurin gudu, da dai sauransu lokacin sarrafa samfuran acrylic don tabbatar da cewa tsarin albarkatun ƙasan acrylic bai lalace ba. Acrylic gabaɗaya abu ne mara ƙarfi. A lokacin yankan CNC, yin amfani da kayan aiki masu dacewa da zurfin yankan da ya dace da sauri zai iya guje wa ɓangarorin sarrafawa da ke haifar da fashewar abu ko zamewa. A cikin ci gaba da yankewa, wajibi ne a fahimci ainihin saurin sarrafawa da zurfin kayan aiki, da kuma kokarin tabbatar da cewa tsarin kayan aiki bai lalace ba, kamar rarrabuwa, cirewa, da dai sauransu A lokaci guda, ya kamata a biya hankali ga rage girman. zafi da lantarki a tsaye yayin sarrafawa.

3. Yi Amfani da Madaidaicin Drill Bit Da Bevel

Tabbatardarawar soja na iya haifar da ramuka da kyau a cikin acrylic ta hanyar zabar kayan aikin da ya dace. Carbide kyakkyawan zaɓi ne don hakowa acrylic, kuma masana'antun da yawa suna amfani da O-groove ƙarshen niƙa rawar soja musamman don yanke da hakowa acrylic. Bugu da ƙari, ƙwanƙwasa ƙwanƙwasa yana buƙatar kiyaye kaifi, ƙwanƙwasa ƙwanƙwasa za su samar da gefuna waɗanda ba su da tsabta kuma suna iya haifar da fashewar damuwa da tsage cikin sauƙi.

Lokacin da CNC machining acrylic, yana da kyau a yi amfani da bevel tare da rawar soja. Don hana raguwar rawar jiki daga lalata abubuwan da ke cikin kayan acrylic, yana buƙatar karkatar da ƙasa tare da gangara mai santsi don hana lalacewa da tabbatar da ƙasa mai santsi.

A lokaci guda, dole ne a kula da zurfin yankan da shugabanci. Jagoran juyawa na kayan aikin CNC: hagu da dama, ko counterclockwise da agogon agogo, dole ne a daidaita shi da dacewa da samfurin don tabbatar da daidaiton aiwatar da samfur da ayyukan ƙira.

Lokacin aikawa: Janairu-16-2024