Copper sassa CNC machining iya samun mai kyau formability a cikin sanyi da zafi machining tafiyar matakai. Bugu da kari, Injiniyas inChengshu kuma havekwarewa mai wadatasa saman jiyya ga tagulla sarrafa kayayyakin da na'urorin haɗi.

Gabaɗaya magana, yawancin kayan tagulla da sassa suna da ingantacciyar injin aiki, ductility, da ƙarfin tasiri, da kuma babban ƙarfin zafin jiki, haɓakawa, juriya na lalata, da juriya.

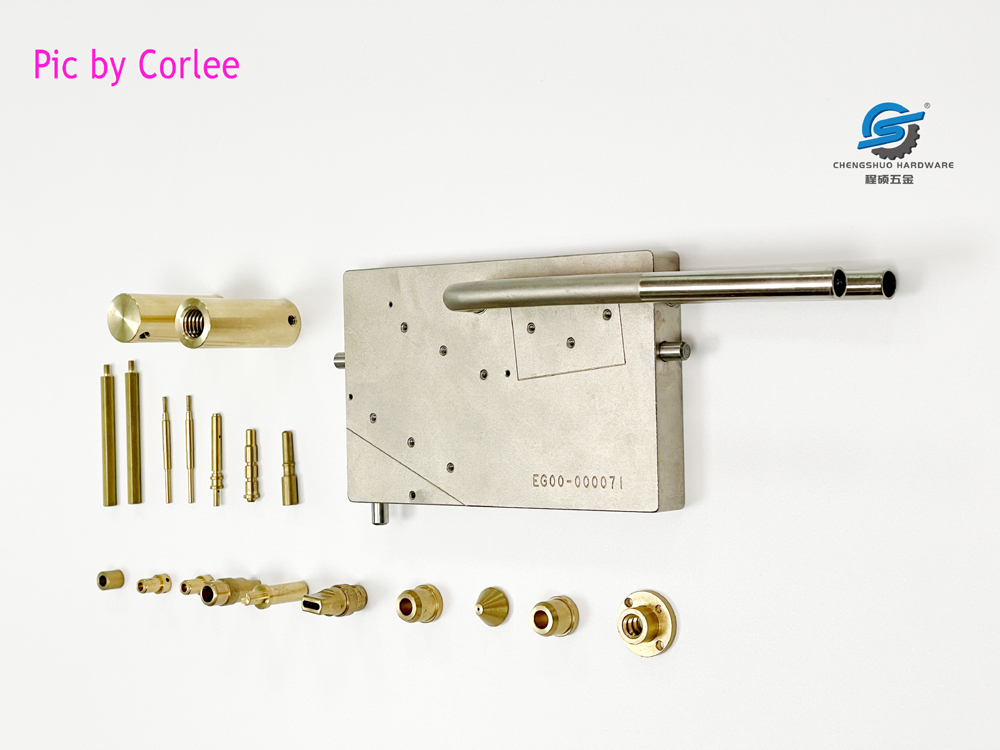

Matakai na Brass/Copper CNC machining

1. Zabi daidaitagulla/darajar jan karfe

Kafin sarrafa tagulla na CNC, dole ne a zaɓi madaidaicin jan ƙarfe wanda ya fi dacewa da kusamfurori' aikace-aikace. Misali, zabar tagulla mai tsafta don kera sassan inji bai dace ba kuma yana da tsada. Sabili da haka, sauƙin yanke jan karfe yana da kayan aiki mai kyau kuma shine abu mafi dacewa. Bugu da kari, su ma suna da tsada-tasiri.Bukatarduba aikin da ake buƙata natagulla/sassa na jan karfe don zaɓar mashin mashin ɗin mashin ɗin daidai.

2. Zane don Ƙarfafawa (DFM)

Kafin sarrafatagulla/tagulla,Injiniyoyi injiniyoyin Chengshuo suna buƙatakuma fahimci buƙatun ƙira da ƙayyadaddun bayanai. Wannan zai taimaka wajen cimma ayyukan da ake buƙata don jan karfetagullasassa. Ka'idar babban yatsan hannu shine amfani da kiyaye kaurin bango na 0.5 millimeters don kera jan ƙarfe mai daɗi da kyau./gudusassa.

3.Saita ƙimar ciyarwar da ta dace

Adadin ciyarwa shine saurin abin da kayan aikin yankan ke haɗawa tare da yanki na aikin. Dole ne a saita ƙimar abinci daidai kafin sarrafa sassan jan karfe, saboda yana shafar inganci, rayuwar sabis, da santsin sassan jan karfe. Bugu da kari, jan karfe/guduyana da saurin haɓakar thermal, kuma babban abincin abinci zai ƙara lalacewa kayan aiki.

4. Zaɓi kayan aiki daidai

Yawancin kayan jan ƙarfe suna da ƙarfi da ƙarfi daban-daban. Sabili da haka, yana da mahimmanci don zaɓar kayan aiki masu dacewa don sarrafa sassan jan karfe, wanda ke taimakawa wajen hana matsaloli irin su lalata kayan aiki da guntuwar guntu.

Bayan jiyya na samfuran jan ƙarfe da aka sarrafa na CNC na kowa

Hanyoyin magani na gama gari don jan karfe/gudusamfuran bayan injin CNC sun haɗa da:

1. Electrolytic polishing

Electrolytic polishing kuma taimaka wajen inganta lalata juriya na ƙãre jan karfe/gudusassa.Lokacin aikin gyaran gyare-gyare na electrolytic, za a cire ƙananan kayan abu daga saman sassan jan karfe. Nisa na wannan abu yawanci shine tsakanin 0.0025 millimeters da 0.063 millimeters, kuma wannan hanyar bayan magani yana taimakawa wajen yin saman da aka gama da tagulla./gudusassa sun fi santsi da haske, kamar plating na nickel.

2. Electroplating

Electroplating yana taimakawa wajen tsawaita rayuwar sabis na jan karfe/gudusassa, da electroplating jan karfe na taimakawa wajen kara kare sararin samaniyar sassan jan karfe daga iskar shaka, ta hanyar magance su ba tare da lalata da sarrafa wutar lantarki da karfin karfen ba.

3. Yashi

Wannan hanyar bayan-aiki yana taimakawa wajen rufe lahani a cikin tagulla/gudusassa. Bugu da ƙari, fashewar yashi na iya sa saman ya fi tsayi, matte, da m.

Lokacin aikawa: Dec-06-2023